Blog

Keep up-to-date with all the latest seating trends, techniques and industry news. We’d love to hear your views, so please join in the discussions or contact us for any information.

Bespoke Seating Detailing – it's all in the details

Unique and Bespoke Detailing to Your Requirements

At Atlas, we understand how important it is to have a manufacturer who can offer you full creative control over all details of your contract furniture, right down to the finest and most intricate details. Our highly skilled team can produce a range of different bespoke seating detailing to create the desired look for your upholstery. Choose the stitching styles, the colour of the thread, any patterns (with bespoke decorative stitching), or why not incorporate the life and soul of your brand with some custom embroidery showcasing your logo. We can create unique, bespoke designs to your exact requirements, with endless possibilities.

What Are Stitching Styles?

For this blog post, we will be taking a closer look at the stitching styles that we offer, a type of bespoke seating detailing. Stitching styles can be functional, such as with a blind seam; used to discretely join panels of upholstery material together – or they can be purely decorative, such as with custom embroidery; often used to incorporate a company’s branding. From subtle details through to intricate designs that completely transform the look of your seating, Atlas are here to help you create your design vision. Distinct stitching styles also form the basis of some of our seating styles. Our ‘Stitch (Sewn-In) Fluted’ and ‘Square Pleated’ back styles are great examples of ways in which stitching styles have been utilised to create an iconic seating style.

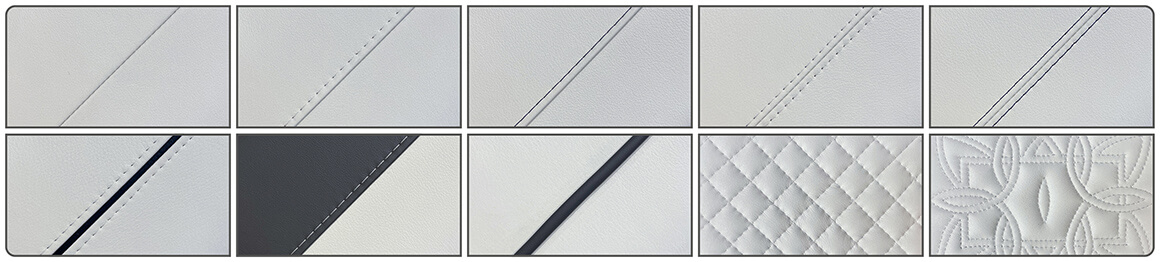

Some of Our Key Stitching Styles

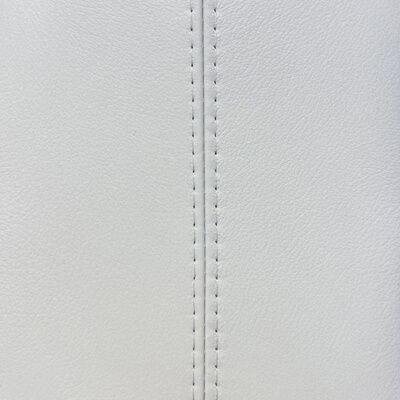

Blind Seam

ABOUT: The blind seam offers an incredibly clean look by concealing the stitching completely between panels of upholstery cover. This discrete seam allows the focus to remain on the seating style and upholstery cover material being used.

PRODUCTION: This functional seam is created by facing the ‘right sides’ of two panels together, then running the seam through the panels to join then. The seam is then laid flat, the correct side up; creating a discrete seam with the seam allowance hidden underneath.

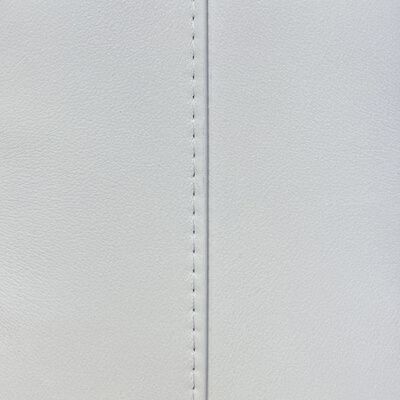

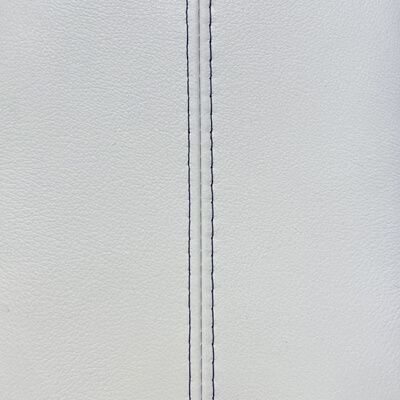

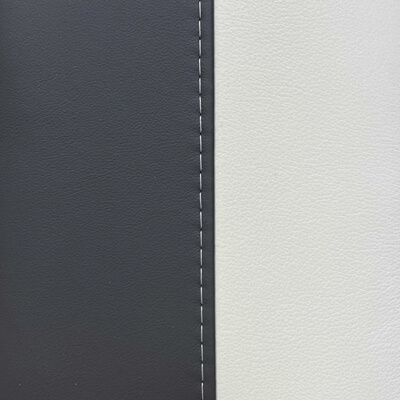

Top Stitch

ABOUT: This is a decorative stitching detail that utilises an additional clean line of thread (running parallel to the original blind seam), to create an extra point of interest. The thread colour can be matched to the upholstery cover, or a contrasting colour can be used to make a design statement. A top stitch also adds extra strength to the seam.

PRODUCTION: Firstly, a blind seam is created between the two pieces of material. The material is oriented the right way up, with the seam allowance (underneath) to one side of the blind seam. Finally, a decorative top stitch is created; running parallel to the blind seam and through the seam allowance underneath. We always top stitch leather, most faux leathers and vinyls. We would not normally top stitch velvets (or anything fluffy), in addition to some soft covers (depending on the material) as they just crush.

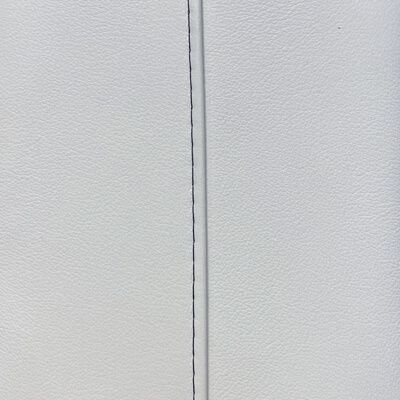

Saddle Stitch

(Elsewhere called ‘Double Top Stitch’ or ‘French Seam’)

ABOUT: Saddle stitches are used to create extra detailing; working particularly well with leathers for a luxury look. As with a top stitch, the thread colours used can either be matched to the upholstery cover, or a contrasting colour can be used on either of the two decorative stitches to make a design statement.

PRODUCTION: Firstly, a blind seam is created between the two pieces of material. On the underside of the blind seam, the seam allowance for each material is pressed flat against the respective material. The seam is then occasionally backed for added strength. The material is then oriented the correct way up. A decorative stitch is then run parallel on either side of the blind seam – both equidistant from the blind seam through that material’s respective seam allowance underneath. As with top stitching, we would not normally saddle stitch velvets (or anything fluffy), as they just crush.

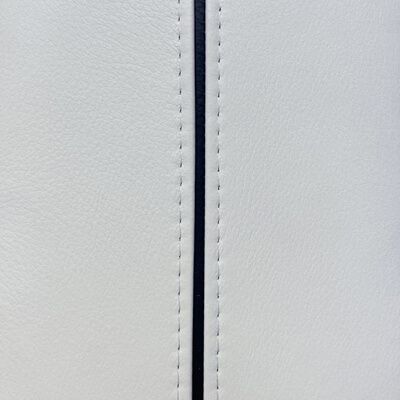

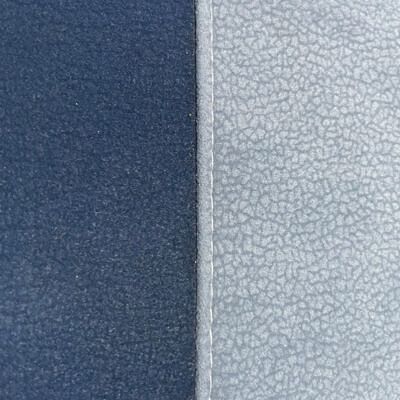

Slot Seam

ABOUT: Slot seams are a decorative stitching technique that offer a high-end, tailored look. They provide an added point of interest with their inset ‘slot’, which can be in matching material to the main upholstery cover or a contrasting one, looking great with both leathers and fabrics. The thread colours can also be customised to match or contrast the upholstery materials.

PRODUCTION: The main panels and slot are prepared. The main material is laid flat, wrong side up, and the seam allowance for each material is pressed flat against itself on each respective side of the blind seam. A strip of material that will form the slot is placed along the flattened seam allowance, also face down. The combined layers of materials are then oriented the correct side up. Stitches are then run parallel on either side of the blind seam – both equidistant from the blind seam through that material’s respective seam allowance and the slot material underneath.

Some of Our Decorative Stitching Styles

Piped Seam and Double Piped Seam

ABOUT: Piping can be used to highlight a distinctive seam, lines, or to define the shape of a design. An example of such would be an option we have for our ‘Square Pleated’ back seating style. A double piped seam is two rows of piping next to each other along the same seam. This can be used to create a classy, high-end look. In addition to those listed in this blog, some other stitching styles incorporate piping directly into them. Please enquire with your requirements for further details.

PRODUCTION: Piping is created by sewing an upholstered cord into a seam; forming a ‘pipe’. Please note that PU faux leathers should never be piped, whereas PVC leathers (which some people mistakenly call faux leathers) can be.

Embroidery

ABOUT: Why not reinforce your corporate identity by incorporating your branding into your seating? We can design furniture with your company colours in mind and add embroidered logos directly into the upholstery cover. It’s a unique way to express your brand, and a memorable touch that is totally personal to your business.

PRODUCTION: Our embroidery service includes digitising your design. There is no real limitation to how small a design can be, whereas they cannot typically be larger than 180 mm x 260 mm. Please enquire if anything larger is required.

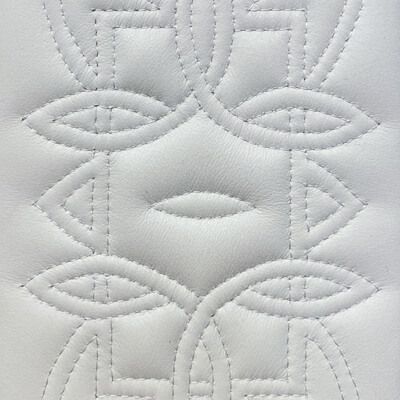

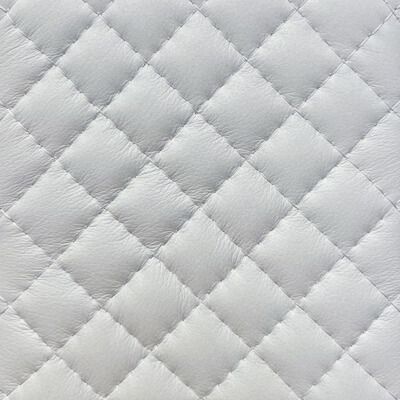

Bespoke Stitching

ABOUT: We can stitch custom details and patterns into your upholstery cover to suit your design requirements. Think elegant diamonds, clean lines, iconic quilting and more. Each of these can be adapted to specification, e.g. one could specify double stitching with a quilted design for an extra luxurious look, or the width of the flutes in our Stitch (Sewn-In) Fluted back seating style.

PRODUCTION: We often stitch bespoke stitching designs through half-inch foam, to give some slight definition and really bring the designs to life. Stitching through a foam will naturally alter the appearance of the design, making it look fuller with slight definition.

Mixing Upholstery Covers

(Colours / Designs / Materials)

It is possible to mix different upholstery colours, designs, and materials throughout most of our seating styles. Whether you wish to create contrast between seat and back, sections of a design (e.g. 3 Horizontal Panel Back), or by joining different styles of panel together to form an upholstery cover (e.g. American diner-style seating; combining white and red upholstery panels), we can materialise your concept with best quality materials and craftsmanship.

We'd Love to Hear About Your Next Project

With Atlas, the possibilities for customisation are endless. We have an impeccable record for producing stunning, functional, made-to-measure seating that meets the exact requirements of our global clients. Why not take a look at our website: atlascontractfurniture.com to browse our gallery for inspiration, view previous case studies, and download our catalogues for further information. Do not hesitate to get in touch – a member of our friendly team would be delighted to discuss your requirements.

Company Policies | Sitemap | Copyright 2025

Website Design and Development by Blue Frontier