Blog

Keep up-to-date with all the latest seating trends, techniques and industry news. We’d love to hear your views, so please join in the discussions or contact us for any information.

How Banquette Seating Is Made

Banquette seating is typically custom-made furniture that goes through a unique manufacturing process. Given that a banquette bench is designed and made to fit a specific space and layout, we have configured a meticulous process to ensure that every piece of made to measure furniture we manufacture suits the exact specifications.

There is a fine art to making banquette seating that we have refined over decades we’ve been operating. As leading contract furniture manufacturers, we’ve broken the process down into the three key stages to help explain how good quality banquette seating is made.

How banquette seating is made: The Design Stage

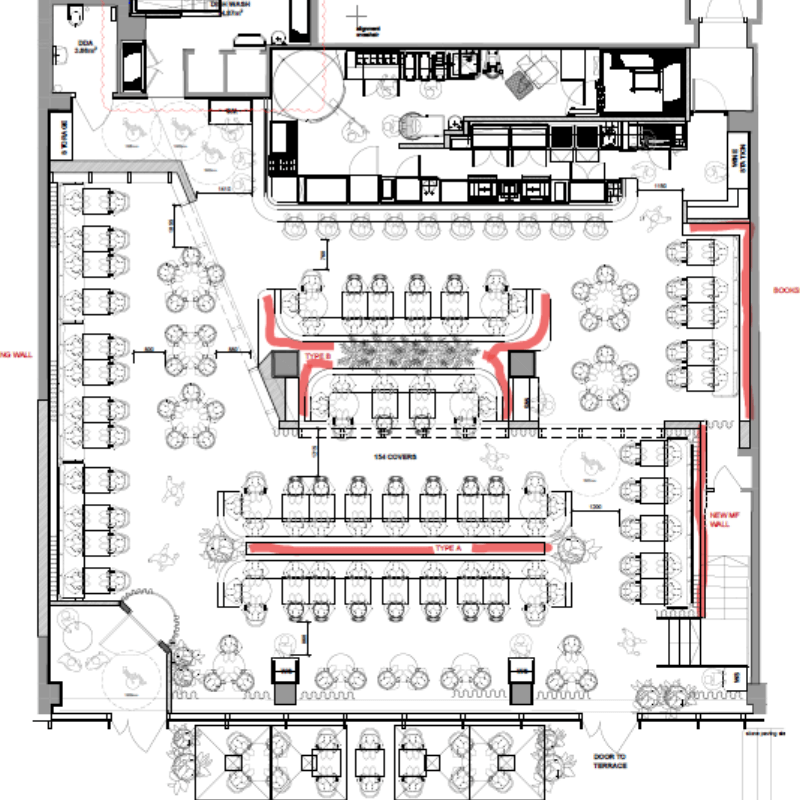

Everything begins with the contract furniture design. Some clients come to us with exact specifications of what they want, providing exact dimensions and floorplans, material choices and seating style which helps streamline our quote time. In most cases however, clients will come to us looking for advice and options.

We have a list of questions we ask all clients to ensure the seating design is exactly fit for purpose:

- What venue will the seating be situated in and the purpose of the seating? E.G. Will users be dining on the seating.

- How many people do you intend to seat at a given time?

- What level of traffic do you expect the seating to be exposed to?

- Is there other furniture in the venue to be mindful of?

Once the intent has been clarified, we can then focus on the design specifications. Understanding the venue type and purpose of the seating helps us advise the best seat construction to ensure the durability of the furniture.

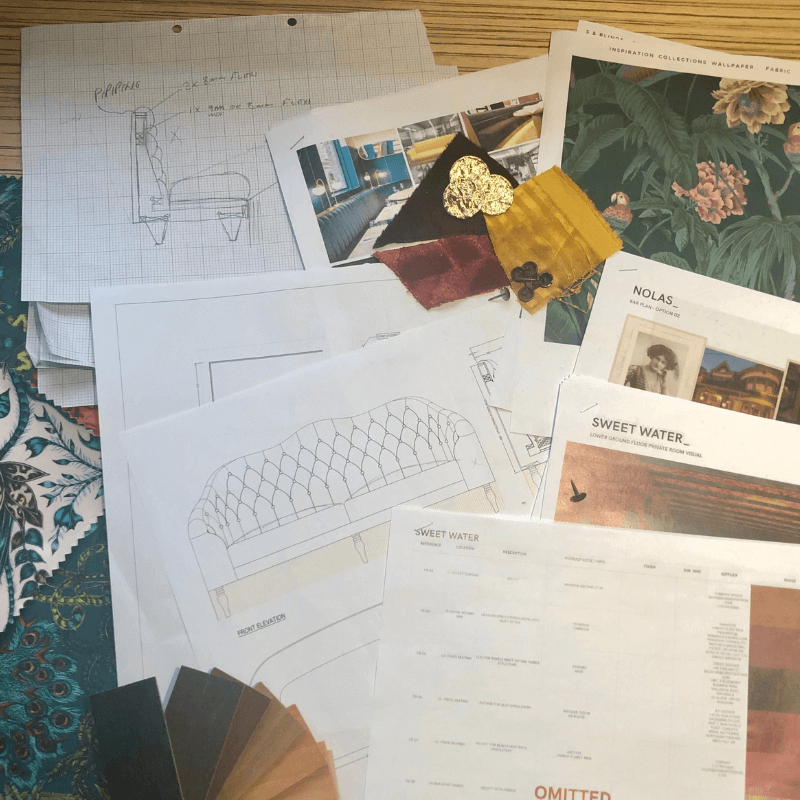

Banquette seating upholstery is another important decision to make when it comes to maintenance and keeping the furniture looking in good condition. We send out samples to help our clients to help choose the right fabric, giving them the chance to feel the fabric and see the colour and pattern. We have more information on how to choose the right upholstery cover fabric here >>

Finally, we'll discuss the back design and style required to make a lasting impression in the space, as well as any bespoke options and additions that complete the design. We can accommodate for requirements such as storage and technical additions like LED strip lighting or power sockets points. We keep our gallery and Pinterest updated with photography of our work to provide inspiration of seating styles and designs.

Once choices have been made and we have the basic dimensions of the furniture, we'll be able to supply a quote that breaks down each specification. The detail of our quotes enables our clients to easily adjust the design to match the budget and get the order confirmed.

How banquette seating is made: The Drawing Stage

Once a project is confirmed and deposit paid, we can move on to the next steps to get the project booked in to our manufacturing and delivery schedule.

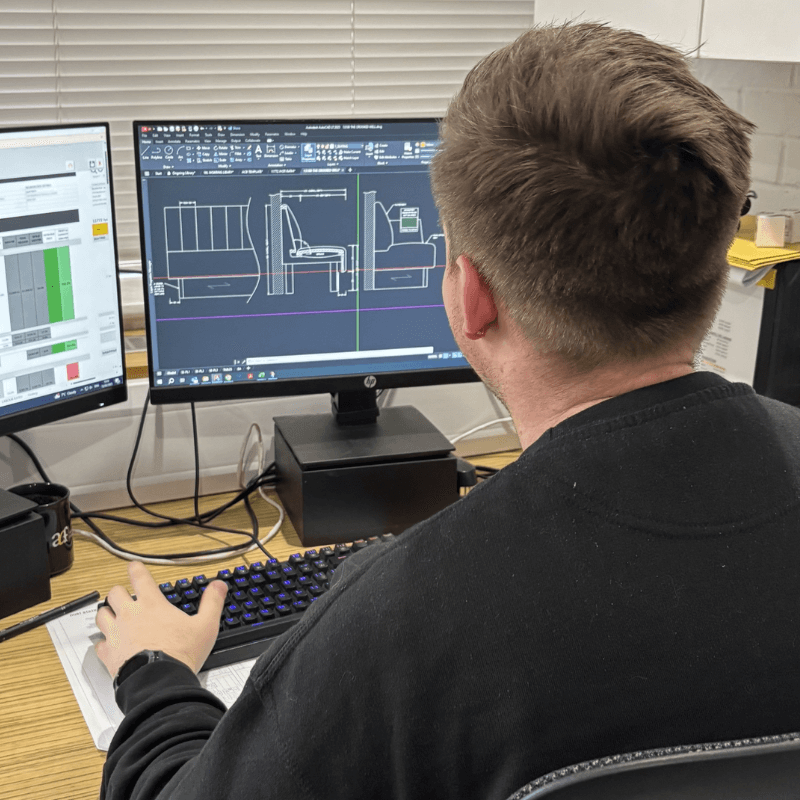

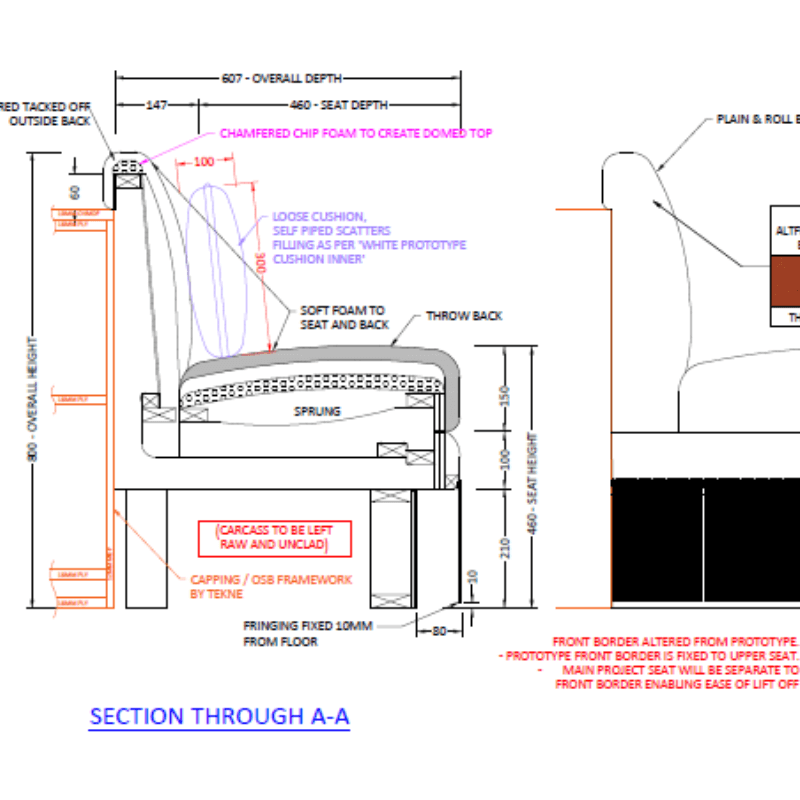

The drawing stage is necessary to provide a detailed view of the finished seating to our clients but also to act as clear instructions for our manufacturing team for the production stage.

In most cases, we undertake a site survey to take precise measurements of the space and scan the area to spot any sticking points, such as angled walls and uneven floors. The site survey will also ensure there are no obstacles when it comes to delivering and installing the bench seating.

Our site surveyor then reports back to our team of CAD experts with any pictures of the venue and the measurements. With these details to hand, the CAD team will draw set outs of the custom furniture. These include plan, section and elevation views of the seating, including precise details around materials and stitching. This provides our clients with a view of exactly what they will receive, and we require our drawings to be fully approved ahead of making the banquette bench.

How banquette seating is made: The Production Stage

Once a project is approved for production, our production manager will schedule the job across each department in our in-house shopfloor:

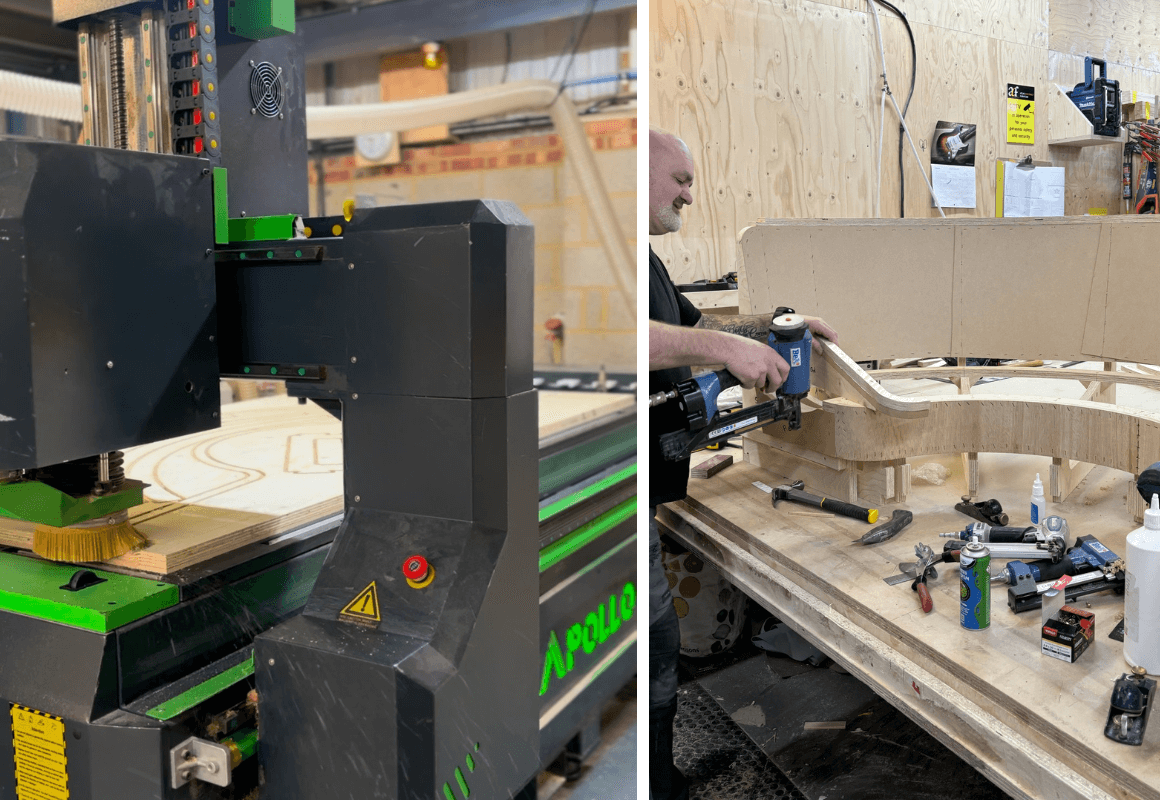

CNC and Joinery

The first stage of production requires cutting out all the parts that form the seating frame. CNC stands for Computer Numerical Control, which is the component cutting machine that precisely cuts out all the parts needed for the framework. Check out our CNC machine in action here. Once the parts have been cut, sanded down and checked for any imperfections, our joinery experts will work on fitting the frame together.

Springs & Padding

Once the basic frame has been assembled, the seating moves up to our prep team. The team attaches the springs and foam based on the detailed drawings and the construction style that was selected in the design stage.

Spray

In the meantime, our highly skilled team of spray finishers will be finishing any exposed surfaces such as plinths, cappings or sides and backs. The team pays close attention to match the colour and finish required.

Upholstery

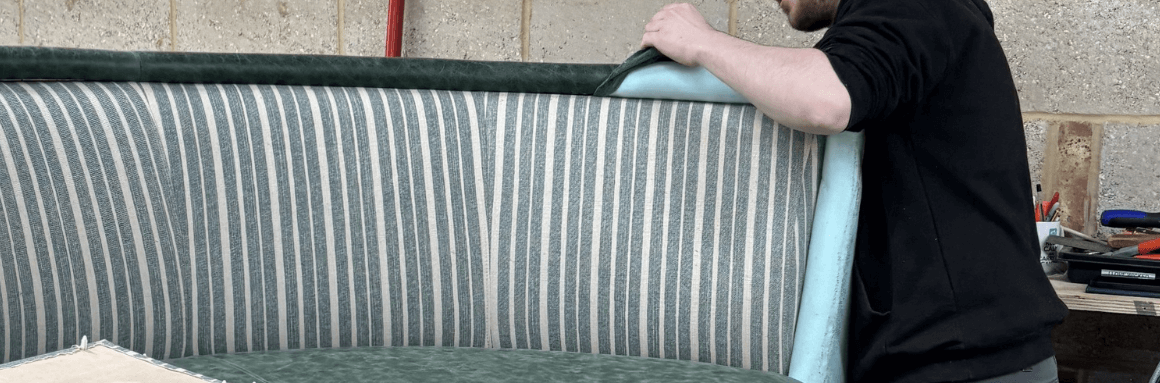

Our skilled upholsterers will plan what shapes are required to cut out of the chosen material for a seamless upholstered look. Once cut, the upholstery cover can be sewn together in the chosen stitching style ready to be fixed to the frame and shape the foam padding.

Pre-assembly and quality control

Once all aspects are ready, we'll assemble the finished custom-made furniture to ensure everything fits together seamlessly, otherwise making necessary adjustments. For larger lengths of seating, we'll connect each section to see the complete banquette bench before it leaves our premises. We do this to give the banquette seat a rigorous quality control check to minimise any problems with installation and ensure the seating stands the test of time.

As you can tell, there is an abundance of craftmanship and skill required at each stage of making banquette seating. That is why it is so important to choose a quality seating manufacturer when opting for any bespoke furniture or contract seating.

Why choose Atlas Contract Furniture

We go above and beyond to take any guess work out of getting bespoke banquette seating made. From delivering high-detail quotes and drawings, to taking expert care and precision at every step of the manufacturing process, we make sure that every piece of furniture that leaves our building is fit for purpose and of outstanding quality. If you're looking to get banquette seating made, then look no further.

Company Policies | Sitemap | Copyright 2025

Website Design and Development by Blue Frontier